-

0 Cart: $ 0.00

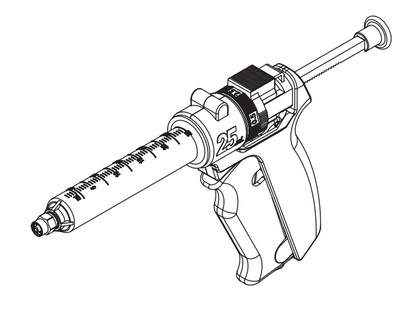

PAS802 (25mL) LIVESTOCK SYRINGE INJECTOR

This 25 mL Plastic Semi-Automatic Repeater by NJ Phillips fills through the tip. It is cost effective, reliable and durable to save you money. Easy choice of 5 fixed dose settings and the built-in needle magazine saves you time. The ergonomic fingertip action reduces hand strain. Optional polypropylene barrel for increased chemical resistance.

The ergonomically designed fingertip action reduces hand strain when giving lots of injections. A comfortable squeeze, built-in needle magazine, and adjustable dosage settings of 1-5 ml. Cost effective, reliable, and durable. Colored knobs sold separately

Front needle medication filling, 25 ml or 50 ml volume repeater syringes with adjustable click-stop dosages. This syringe has a push grip for more natural motion when giving injections. Amber colored barrel reduces UV sunlight exposure. Durable construction with metal and plastic components designed for rugged conditions. Barrel and needle attachment can be autoclaved to ensure proper sterilization and pathogen control. Popular syringe for all livestock operations.

INSTRUCTIONS FOR USE

Sterilization:

It is essential that this instrument and a supply of needles be thoroughly sterilized before each use. We recommend a cold water sterilant solution be used to sterilise the applicator before each use. Follow cold sterilant manufacturer’s instructions for sterilisation procedure. If cold water sterilisation is not available, a common method of sterilization is as follows:

1 Draw hot water into the cylinder.

2 Suspend complete instrument in a container of water so it does not touch the bottom. Boil together with the needles for 10 minutes.

3 Remove instrument from container, wrap cloth around handle and pump dry. Filling Before filling from a rubber-sealed glass bottle, ensure that the release locking ring is positioned fully back to disengage the ratchet, allowing the push rod to move freely in either direction. Withdraw push rod fully, expel all air and set injector to the required maximum capacity.

Fit needle to syringe and pierce rubber bung on inverted bottle. Introduce air into bottle by pushing the push rod end knob. Then, keeping bottle inverted, draw liquid into the cylinder. Repeat this procedure until the syringe is fully charged. Presence of excessive air bubbles indicates an air leak in the instrument or incorrect filling technique. Dose Setting Set the dose by turning the dose adjustor (13 or 14) until the required dose is aligned with the arrow on the top of the instrument. Care must be taken to ensure the liquid does not come into contact with any part of the operators body. Chemicals may cause injury to the operator.

CLEANING AND MAINTENANCE AFTER USE

1 Remove all traces of material from syringe by flushing thoroughly with a hot water detergent mix. Follow with clean, warm water.

2 Lubricate piston by unscrewing the cylinder and placing a small quantity of NJ Phillips Lubricant, onto the ‘0’ ring (7 or 8).

3 Place a few drops of NJ Phillips Lubricant on all moving parts.

4 When replacing the cylinder, make sure that the push rod is fully back for ease of location, otherwise damage to the cylinder could occur. DO NOT store your applicator or feed tube full of product. Clean as per the “Care and Maintenance” instructions.

REPLACING PISTON RING

Should it become necessary to replace the piston seal ring, the subsequent procedure must be followed.

1 Pull push rod fully back.

2 Unscrew cylinder from handle.

3 Remove worn ‘0’ ring from piston, taking care not to damage the groove.

4 Lubricate new ring with NJ Phillips Lubricant and fit to piston.

5 Replace cylinder as directed in Care and Maintenance.

Do not attempt to dismantle the dose adjustor assembly as this should never be necessary.

PAS802 (25mL) LIVESTOCK SYRINGE INJECTOR

This 25 mL Plastic Semi-Automatic Repeater by NJ Phillips fills through the tip. It is cost effective, reliable and durable to save you money. Easy choice of 5 fixed dose settings and the built-in needle magazine saves you time. The ergonomic fingertip action reduces hand strain. Optional polypropylene barrel for increased chemical resistance.

The ergonomically designed fingertip action reduces hand strain when giving lots of injections. A comfortable squeeze, built-in needle magazine, and adjustable dosage settings of 1-5 ml. Cost effective, reliable, and durable. Colored knobs sold separately

Front needle medication filling, 25 ml or 50 ml volume repeater syringes with adjustable click-stop dosages. This syringe has a push grip for more natural motion when giving injections. Amber colored barrel reduces UV sunlight exposure. Durable construction with metal and plastic components designed for rugged conditions. Barrel and needle attachment can be autoclaved to ensure proper sterilization and pathogen control. Popular syringe for all livestock operations.

INSTRUCTIONS FOR USE

Sterilization:

It is essential that this instrument and a supply of needles be thoroughly sterilized before each use. We recommend a cold water sterilant solution be used to sterilise the applicator before each use. Follow cold sterilant manufacturer’s instructions for sterilisation procedure. If cold water sterilisation is not available, a common method of sterilization is as follows:

1 Draw hot water into the cylinder.

2 Suspend complete instrument in a container of water so it does not touch the bottom. Boil together with the needles for 10 minutes.

3 Remove instrument from container, wrap cloth around handle and pump dry. Filling Before filling from a rubber-sealed glass bottle, ensure that the release locking ring is positioned fully back to disengage the ratchet, allowing the push rod to move freely in either direction. Withdraw push rod fully, expel all air and set injector to the required maximum capacity.

Fit needle to syringe and pierce rubber bung on inverted bottle. Introduce air into bottle by pushing the push rod end knob. Then, keeping bottle inverted, draw liquid into the cylinder. Repeat this procedure until the syringe is fully charged. Presence of excessive air bubbles indicates an air leak in the instrument or incorrect filling technique. Dose Setting Set the dose by turning the dose adjustor (13 or 14) until the required dose is aligned with the arrow on the top of the instrument. Care must be taken to ensure the liquid does not come into contact with any part of the operators body. Chemicals may cause injury to the operator.

CLEANING AND MAINTENANCE AFTER USE

1 Remove all traces of material from syringe by flushing thoroughly with a hot water detergent mix. Follow with clean, warm water.

2 Lubricate piston by unscrewing the cylinder and placing a small quantity of NJ Phillips Lubricant, onto the ‘0’ ring (7 or 8).

3 Place a few drops of NJ Phillips Lubricant on all moving parts.

4 When replacing the cylinder, make sure that the push rod is fully back for ease of location, otherwise damage to the cylinder could occur. DO NOT store your applicator or feed tube full of product. Clean as per the “Care and Maintenance” instructions.

REPLACING PISTON RING

Should it become necessary to replace the piston seal ring, the subsequent procedure must be followed.

1 Pull push rod fully back.

2 Unscrew cylinder from handle.

3 Remove worn ‘0’ ring from piston, taking care not to damage the groove.

4 Lubricate new ring with NJ Phillips Lubricant and fit to piston.

5 Replace cylinder as directed in Care and Maintenance.

Do not attempt to dismantle the dose adjustor assembly as this should never be necessary.